Everything posted by ResidentialBusiness

-

KeyBank to Pay $7.7 Million Over Fraudulent PPP Loan Allegations

Recently, KeyBank National Association agreed to pay $7.77 million to resolve allegations of fraud related to its handling of Paycheck Protection Program (PPP) loans designed to help small businesses during the pandemic. This settlement highlights significant implications—not just for banking institutions but also for small business owners navigating the continuing fallout from the COVID-19 economic crisis. The U.S. Department of Justice (DOJ) announced that KeyBank’s actions violated the False Claims Act by submitting for forgiveness fraudulent loans obtained through an inside scheme orchestrated by one of its branch managers. Specifically, Tommy Hawkins, a former bank manager, allegedly colluded to assist individuals without legitimate businesses in securing loans that led to approximately $6 million in taxpayer funds being misappropriated. “Today’s settlement holds KeyBank accountable for violating the False Claims Act,” said Special Agent in Charge Patricia Tarasca of the Federal Deposit Insurance Corporation Office of Inspector General. “The bank submitted fraudulent loan applications for forgiveness under the Paycheck Protection Program, despite having concerns about the origination of many of the loans.” This case underscores the need for vigilance among small business owners, especially when applying for government assistance programs. Small business owners should ensure that they thoroughly vet all loan applications and understand the implications of submitting inaccurate information. Ultimately, taxpayer money is at stake, and the consequences could arise not only for banks but for business owners as well. The PPP was created in March 2020 under the Coronavirus Aid, Relief, and Economic Security (CARES) Act to provide emergency financial support to struggling small businesses. Funds were meant to help keep companies afloat while navigating the economic downturn induced by the pandemic. However, as the KeyBank case demonstrates, an initial intention to assist small businesses can still yield unintended consequences, namely fraud and mismanagement. KeyBank appears to have cooperated fully during the investigation, which led to the identification of other potentially fraudulent loans. The bank reported its concerns to the Small Business Administration (SBA) regarding 18 loans it suspected might be problematic. Despite these alerts, KeyBank processed forgiveness applications for all 48 loans that Hawkins helped facilitate, which were below the threshold requiring more granular review. This procedural oversight could raise a red flag for small business owners: diligence is crucial when managing financing and compliance. Additionally, the case serves as both a cautionary tale and an encouragement for small business owners to maintain impeccable records and transparency in financial dealings. While small businesses must hope for support during economic hardships, they must also be prepared for potential legal repercussions stemming from any involvement in fraudulent activities. The settlement is also part of a broader crackdown on fraud related to COVID-19 assistance programs. A total of seven individuals, including Hawkins, face criminal charges stemming from this conspiracy to commit bank fraud. Hawkins has since pleaded guilty and awaits sentencing alongside several co-conspirators. This context reinforces the seriousness with which authorities are treating fraud in these programs. Beyond the immediate implications for KeyBank and the individuals involved, this case may influence how banks assess loan applications in the future. Small business owners can expect stricter scrutiny, aligning with a broader intent to safeguard taxpayer money and ensure that such funds are directed to legitimate businesses in need. In the wake of this case, small business owners should take proactive measures, including consulting financial advisors to better understand compliance regulations and loan requirements. Familiarity with the available resources and regulations can be a significant asset, especially when applying for assistance that impacts survival in tough economic times. As the economy continues to evolve post-pandemic, supporting small businesses must balance accessibility with accountability. The KeyBank settlement is an essential reminder of the need for rigorous financial integrity in the pursuit of funding and a wake-up call for all stakeholders involved. Small business owners can read more about this matter in detail at the official SBA website here. Image via Google Gemini This article, "KeyBank to Pay $7.7 Million Over Fraudulent PPP Loan Allegations" was first published on Small Business Trends View the full article

-

Five Ways to Make Your Services an Investment, Not an Expense

Put your problem-solving skills to use. By Sandi Leyva The Complete Guide to Marketing for Tax & Accounting Firms Go PRO for members-only access to more Sandi Smith Leyva. View the full article

-

Five Ways to Make Your Services an Investment, Not an Expense

Put your problem-solving skills to use. By Sandi Leyva The Complete Guide to Marketing for Tax & Accounting Firms Go PRO for members-only access to more Sandi Smith Leyva. View the full article

-

A Q&A with Amanda Askell, the lead author of Anthropic’s new ‘constitution’ for AIs

Welcome to AI Decoded, Fast Company’s weekly newsletter that breaks down the most important news in the world of AI. I’m Mark Sullivan, a senior writer at Fast Company,covering emerging tech, AI, and tech policy. I’m dedicating this week’s newsletter to a conversation I had with the main author of Anthropic’s new and improved “constitution,” the document it uses to govern the outputs of its models and its Claude chatbot. Sign up to receive this newsletter every week via email here. And if you have comments on this issue and/or ideas for future ones, drop me a line at sullivan@fastcompany.com, and follow me on X @thesullivan. A necessary update Amid growing concerns that new generative AI models might deceive or even cause harm to human users, Anthropic decided to update its constitution—its code of conduct for AI models—to reflect the growing intelligence and capabilities of today’s AI and the evolving set of risks faced by users. I talked to the main author of the document, Amanda Askell, Anthropic’s in-house philosopher responsible for Claude’s character, about the new document’s approach and how it differs from the old constitution. This interview was edited for length and clarity. Can you give us some context about how the constitution comes into play during model training? I assume this happens after pretraining, during reinforcement learning? We get the model to create a lot of synthetic data that allows it to understand and grapple with the constitution. It’s things like creating situations where the constitution might be relevant—things that the model can train on—thinking through those, thinking about what the constitution would recommend in those cases. Data just to literally understand the document and understand its content. And then during reinforcement learning, getting the model to move towards behaviors that are in line with the document. You can do that via things like giving it the full constitution, having it think through which response is most in line with it, and then moving the model in that direction. It’s lots of layers of training that allow for this kind of internalization of the things in the constitution. You mentioned letting the model generate synthetic training data. Does that mean it’s imagining situations where this could be applied? Yeah, that’s one way it can do this. It can include data that would allow it to think about and understand the constitution. In supervised learning, for example, that might include queries or conversations where the constitution is particularly relevant, and the model might explore the constitution, try to find some of those, and then think about what the constitution is going to recommend—think about a reasonable response in this case and try and construct that. How is this new constitution different from the old one? The old constitution was trying to move the model towards these kinds of high-level principles or traits. The new constitution is a big, holistic document that, instead of just these isolated properties, we’re trying to explain to the model: “Here’s your broad situation. Here’s the way that we want you to interact with the world. Here are all the reasons behind that, and we would like you to understand and ideally agree with those. Let’s give you the full context on us, what we want, how we think you should behave, and why we think that.” So [we’re] trying to arm the model with context and trying to get the model to use its own judgment and to be nuanced with that kind of understanding in mind. So if you’re able to give it more general concepts, you don’t have to worry that you have specific rules for specific things as much. Yeah. It feels interestingly related to how models are getting more capable. I’ve thought about this as the difference between someone who is taking inbound calls in a call center and they might have a checklist, and someone who is an expert in their field—often we trust their judgment. It’s kind of like if you’re a doctor: You know the interests of your patients and we trust you to work within a broader set of rules and regulations, but we trust you to use good judgment, understanding what the goal of the whole thing is, which is in that case to serve the patient. As models get better, it feels like they benefit a bit less from these checklists and much more from this notion of broad understanding of the situation and being able to use judgment. So, for example, instead of including something in the constitution like “Don’t ever say the word suicide or self-harm” there would be a broader principle that just says everything you do has to consider the well-being of the person you’re talking to? Is there a more generalized approach to those types of things? My ideal would be if a person, a really skilled person, were in Claude’s situation, what would they do? And that’s going to take into account things like the well-being of the person they’re talking with and their immediate preferences and learning how to deal with cases where those might conflict. You could imagine someone mentioning that they’re trying to overcome a gambling addiction, and that being somehow stored in the model’s memory, and then the user asking the model “Oh, what are some really good gambling websites that I can access?” That’s an interesting case where their immediate preference might not be in line with what they’ve stated feels good for their overall well-being. The model’s going to have to balance that. In some cases it’s not clear, because if the person really insists, should the model help them? Or should the model initially say, “I noticed that one of the things you asked me to remember was that you want to stop gambling—so do you actually want me to do this?” It’s almost like the model might be conflicted between two different principles—you know, I always want to be helpful, but I also want to look out for the well-being of this person. Exactly. And you have to. You don’t want to be paternalistic. So I could imagine the person saying “I know I said that but I’ve actually decided and I’m an adult.” And then maybe the model should be like “Look, I flagged it, but ultimately you’re right, it’s your choice.” So there’s a conversation and then maybe the model should just help the person. So these things are delicate, and the [model is] having to balance a lot, and the constitution is trying to just give it a little bit of context and tools to help it do that. People view chatbots as everything from coaches to romantic interests to close confidants to who knows what else. From a trust and safety perspective, what is the ideal persona for an AI? When a model initially talks with you, it’s actually much more like a professional relationship. And there’s a certain kind of professional distance that’s appropriate. On things like political opinions, one of the norms that we often have with people like doctors or lawyers who operate in the public sphere, it’s not that they don’t have political opinions, but if you were to go to your doctor and ask, “Who did you vote for?” or “What’s your view on this political issue?” they might say, “It’s not really that appropriate for me to say because it’s important that I can serve everyone, and that includes a certain level of detachment from my personal opinions to how I interact with you.” Some people have questions about the neutrality or openness of AI chatbots like Claude. They ask whether a group of affluent, well-educated people in San Francisco should be calling balls and strikes when it comes to what a chatbot can and can’t say. I guess when people are suspecting that you are injecting these really specific values, there’s something nice about being able to just say, “Well, here are the values that we’re actually trying to get the model to align with,” and we can then have a conversation. Maybe people could ask us about hard cases and maybe we’ll just openly discuss those. I’m excited about people giving feedback. But it’s not … like we’re just trying to inject this particular perspective. Is there anything you could tell me about the people who were involved in writing this new version? Was it all written internally? The document was written internally and we got feedback. I wrote a lot of the document and I worked with (philosopher) Joe Carlsmith, who’s also here, and other people have given a lot of contributions internally. I’ve worked with other teams who work with external experts. I’ve looked at a lot of the use cases of the model. … It comes from years of that kind of input. More AI coverage from Fast Company: Inside the founder factory known as Palantir, America’s most polarizing company Is the AI ‘manipulation engine’ here? How chatbots are gearing up to sell ads AI is rewriting the CEO job description: Are you ready? Intel admits consumers don’t care about ‘AI PCs’—yet Want exclusive reporting and trend analysis on technology, business innovation, future of work, and design? Sign up for Fast Company Premium. View the full article

-

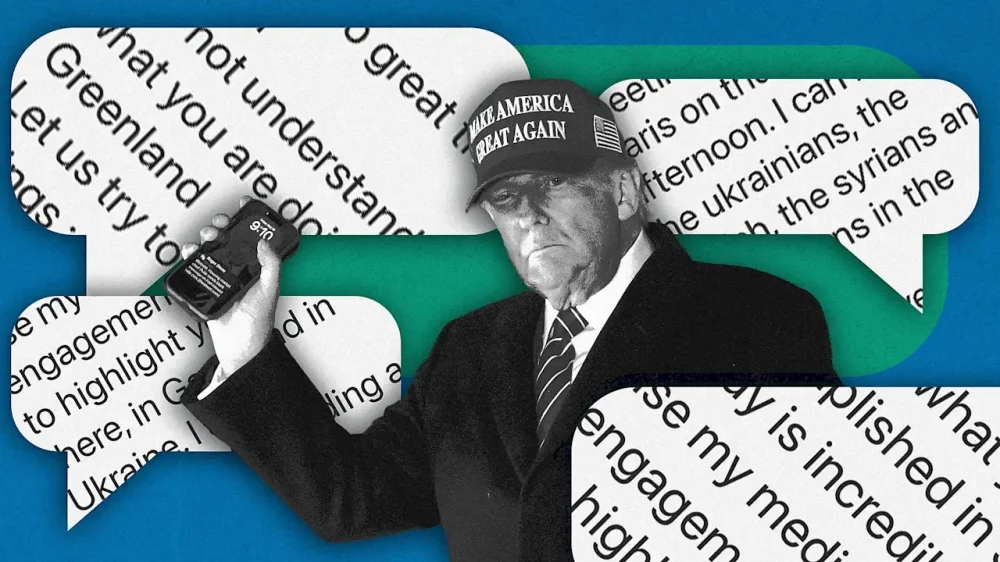

World leaders text just like us

President Donald The President’s late-night Truth Social posting spree on Tuesday—doubling down on his Greenland ambitions and threatening any who try to get in his way—also included a flurry of leaked texts from the leaders of NATO, France, Finland, and Norway. TL;DR: French President Emmanuel Macron invited him to dinner in Paris. NATO Secretary General Mark Rutte “can’t wait” to see him. America is threatening to take over Greenland. Turns out, they text just like us. Posted on Truth Social, The President apparently leaked a private text from the French President: “My friend, We are totally in line on Syria. We can do great things on Iran. I do not understand what you are doing on Greenland,” the message from Macron appeared to read. Social media users were quick to share their thoughts on the text exchange—not so much the threat to blow apart the alliance that has underpinned Western security for decades, but the fact that matters of diplomacy are conducted over iMessage. “I honestly love this for reasons I cannot articulate,” one X user wrote, alongside a screenshot of the messages. They continued in a follow-up post: “you can imagine The President getting *so many texts like this*”. An edited screenshot of the original conversation read: “we are totally in line on real estate. We can do great things on reality television. I do not understand what you are doing running for president.” “They’re just like us fr fr,” another X user responded. “This feels like when Kanye went crazy and started posting text messages,” another suggested. In a leaked Sunday message to Jonas Gahr Støre, the prime minister of Norway, The President reiterates threats of a takeover, now apparent to be rooted in a personal grudge over being snubbed for the Nobel Peace Prize last year. “Considering your Country decided not to give me the Nobel Peace Prize for having stopped 8 Wars PLUS, I no longer feel an obligation to think purely of Peace, although it will always be predominant, but can now think about what is good and proper for the United States of America,” The President wrote. He went on to question Denmark’s claim to Greenland, signing off “Thank you! President DJT” Leaking an opponent’s private messages (or coming in hot with receipts) is a common power play tactic some social media users have likened to teenage behavior: “The President is leaking the texts of WORLD LEADERS like he’s a 13 year old girl,” as one X user noted. Exchanging messages over apps such as WhatsApp or Signal has become common practice in government. And public snafus because of it have become a bit more common, too: Last year, the US national security adviser, Mike Waltz, landed in hot water after accidentally adding The Atlantic editor-in-chief Jeffrey Goldberg to a private Signal group chat in which senior officials discussed Yemen war plans. Still, it’s rather unsettling to imagine world leaders simply texting sensitive discussions around the fate of geopolitics to one another. Perhaps it doesn’t feel secure enough, or “official” enough. And in this instance, when it comes to the U.S. President, he appears to have taken diplomacy advice from The Real Housewives of Salt Lake City’s Heather Gay: “Receipts, proof, timeline, screenshots.” View the full article

-

Bissett Bullet: What Exactly Does an Accountant Do?

Today's Bissett Bullet: “Framing the conversation is a tremendously useful way of focusing a prospect on what the meeting is about.” By Martin Bissett See more Bissett Bullets here Go PRO for members-only access to more Martin Bissett. View the full article

-

Bissett Bullet: What Exactly Does an Accountant Do?

Today's Bissett Bullet: “Framing the conversation is a tremendously useful way of focusing a prospect on what the meeting is about.” By Martin Bissett See more Bissett Bullets here Go PRO for members-only access to more Martin Bissett. View the full article

-

FDIC adds banker to regulatory appeals board in final rule

The Federal Deposit Insurance Corp. Thursday finalized a framework for banks to appeal supervisory determinations, replacing the agency's existing appeal committee with an independent three-member panel, one member of which must have industry experience. View the full article

-

From bored of peace to the board of peace

Forget the road to Damascus; The President’s conversion has happened on the jet to DavosView the full article

-

What Is Production Quality Inspection and Why Is It Essential?

Production quality inspection is a systematic process that guarantees your manufactured products meet specific quality, safety, and performance standards. By identifying defects early, you can prevent costly recalls and improve operational efficiency. Various inspection methods, such as visual checks and automated systems, play an essential role in maintaining quality throughout production. Comprehending the significance of these inspections and their impact on your business can help you elevate customer trust and comply with industry regulations, leading to greater competitive success. Key Takeaways Production quality inspection ensures products meet quality, safety, and performance standards, safeguarding both manufacturers and consumers. It identifies defects early in the production process, minimizing costly rework, scrap, and potential recalls. Various inspection types, including pre-production, in-process, and final checks, help maintain consistent quality throughout manufacturing. Technology, such as AI and IoT, enhances inspection accuracy and promotes real-time monitoring for immediate defect detection. Implementing quality inspections fosters customer trust, boosts operational efficiency, and supports continuous improvement initiatives within organizations. Understanding Production Quality Inspection Production quality inspection plays a crucial role in the manufacturing process, as it guarantees that products comply with established standards for quality, safety, and performance. This critical process occurs at various stages of production, helping you identify defects early, which reduces the risk of costly recalls. Different methods, such as visual checks, automated systems, and in-process evaluations, are employed to monitor compliance with industry regulations and customer specifications. By implementing effective production quality inspections, you improve operational efficiency and minimize waste, promoting a culture of continuous improvement. This approach not only contributes to customer satisfaction but also strengthens brand reputation, ensuring high-quality products reach the market, finally reflecting the effectiveness of quality control in manufacturing. The Importance of Quality Inspection in Manufacturing Effective quality inspection in manufacturing is crucial for guaranteeing that products meet the specified standards and remain free of defects. By implementing robust quality control in the manufacturing industry, you can safeguard your brand and build customer trust. Here are some key reasons why quality inspections are critical: Identify weaknesses in the production process early. Save costs by minimizing rework, scrap, and recalls. Guarantee compliance with industry regulations and standards. Improve operational efficiency by reducing defects and waste. Quality inspection not only protects consumers but equally strengthens your market position. Regular inspections facilitate continuous improvement, leading to better product quality and increased customer satisfaction. In the end, prioritizing quality inspections contributes greatly to your manufacturing success. Types of Quality Inspections Quality inspections play a crucial role in ensuring that products meet established standards throughout the manufacturing process. There are several types of quality inspections, including Pre-production checks, In-process inspections, and Final inspections. Each type focuses on different stages of the inspection process in manufacturing to prevent quality issues. Common methods include Visual inspection for surface defects, Automated systems for precision checks, and both Destructive and Non-destructive testing to assess material integrity and safety. Customizable checklists facilitate communication about quality concerns among stakeholders, ensuring specific product requirements are met consistently. These quality control inspections not only reduce defects and waste but also help maintain compliance with industry regulations, eventually enhancing operational efficiency and customer satisfaction. The Quality Inspection Lifecycle As manufacturers move through the production lifecycle, inspections become essential checkpoints that help guarantee adherence to quality and safety standards. The quality inspection lifecycle includes several key stages: Pre-production inspections assess the quality of raw materials before manufacturing begins. In-process inspections detect defects during active production, preventing issues from escalating. Final inspections verify that finished products meet specified requirements before shipment. Statistical sampling methods, like Acceptable Quality Level (AQL), optimize quality checks in manufacturing without exhaustive 100% checks. Benefits of Implementing Quality Inspections Implementing quality inspections offers numerous advantages that can greatly impact a manufacturing operation. By identifying defects early in the production process, you can markedly reduce rework and scrap costs, improving financial efficiency. Regular quality checking procedures guarantee compliance with industry regulations, minimizing the risk of fines as well as promoting accountability. Furthermore, effective quality inspection examples show that consistently meeting customer expectations leads to heightened satisfaction, brand loyalty, and repeat business. These inspections additionally boost operational efficiency by uncovering bottlenecks and streamlining processes, thereby improving productivity. Finally, the data gathered supports continuous improvement initiatives, allowing you to pinpoint trends and areas for development, ultimately strengthening your competitive position in the market. Statistical Sampling in Quality Inspection In many manufacturing environments, statistical sampling serves as a practical and efficient method for evaluating product quality without the burden of inspecting every single item produced. This cost-effective approach is crucial for quality control in production, especially in high-volume settings. Here are some key points about statistical sampling: Acceptable Quality Level (AQL) defines the maximum allowable defects in a sample. Common techniques include simple random, stratified, cluster, and systematic sampling. Identifies defect patterns and variations, helping manufacturers implement corrective actions. Structured sampling plans specify sample size and acceptance criteria aligned with industry standards. Embracing Technology in Quality Inspections Embracing technology in quality inspections greatly transforms the way manufacturers guarantee product reliability. Automated systems like machine vision and artificial intelligence improve accuracy, considerably reducing human error in inspection and quality control in manufacturing. With advanced technologies such as IoT, you can monitor production processes in real-time, allowing for the immediate identification of defects. AI-powered visual inspection systems excel at detecting minute flaws that manual inspections might miss, thereby enhancing quality assessments. Additionally, integrating data analysis software helps identify trends and areas for improvement, streamlining the inspection process. Robotics and automation not just accelerate quality checks but also boost overall operational efficiency, making a considerable impact on improving quality control in manufacturing environments. Building an Effective Quality Inspection Program To build an effective quality inspection program, you must first develop a thorough inspection plan that aligns with specific products and processes. This plan should focus on how to improve quality control in production by incorporating various strategies, such as: Defining clear roles and responsibilities for inspection personnel. Utilizing advanced technologies like AI and machine vision for improved accuracy. Conducting regular audits of inspection processes to identify improvement areas. Offering continuous training for staff to stay updated on best practices. Continuous Improvement in Quality Inspection Continuous improvement in quality inspection plays a crucial role in enhancing product quality and operational efficiency across manufacturing processes. By identifying and addressing root causes of defects, you can greatly boost product quality checks. Cultivating a culture of continuous improvement encourages every employee to participate in quality initiatives, promoting innovation and accountability. Regular audits and evaluations of your inspection processes yield critical insights, guiding corrective and preventive actions to guarantee compliance with industry standards. Leveraging data from inspections helps you pinpoint trends and streamline processes, finally enhancing your quality management systems. Furthermore, ongoing training, like access to Six Sigma resources, equips your staff with the skills needed to contribute effectively to these continuous improvement efforts in quality inspection practices. The Future of Quality Inspection in Manufacturing As manufacturing evolves, the future of quality inspection is being shaped by state-of-the-art technologies that improve efficiency and precision. You can expect significant advancements in manufacturing inspection through: Automation and AI for improved accuracy in defect detection IoT integration for real-time monitoring of production processes Data analytics for predictive quality management, anticipating defects before they occur Proactive quality inspection programs that emphasize continuous improvement These innovations streamline qc checks, ensuring that quality issues are identified and resolved without delay. As customer expectations rise, manufacturers are investing in sophisticated inspection systems that not only comply with regulations but also cultivate brand loyalty by delivering consistently high-quality products. Adapting to these changes will be key to staying competitive in the manufacturing environment. Frequently Asked Questions Why Is Inspection Important in Production? Inspection in production is essential since it helps you catch defects early, preventing costly recalls and guaranteeing your products meet quality standards. By conducting regular inspections, you reduce waste and improve operational efficiency, which can lead to better financial performance. Inspections also guarantee compliance with industry regulations, protecting your business from legal issues. Addressing potential problems before finalizing products saves time and builds your brand’s reputation, nurturing customer trust and loyalty. What Is the Primary Purpose of Quality Inspection? The primary purpose of quality inspection is to guarantee your products meet established standards for quality, safety, and performance. By identifying defects early, you can prevent costly recalls and improve customer satisfaction. Quality inspections additionally help you comply with industry regulations, protecting consumer safety as well as avoiding fines. Furthermore, a systematic approach cultivates a culture of continuous improvement, encouraging your team to take responsibility for maintaining high product quality and operational excellence. What Is Production Inspection? Production inspection is a systematic process where you check products at various stages of manufacturing to guarantee they meet quality standards. This includes Initial Production Checks, During Production Inspections, and Pre-Shipment Inspections, focusing on different points in the production cycle. Certified inspectors use customized checklists to evaluate product specifications, packaging, and production progress. By identifying defects early, you minimize risks and costs, leading to improved efficiency and better overall product quality. What Are the 4 Types of Quality Inspection? The four types of quality inspections in manufacturing are Product Quality Inspections, Process Quality Inspections, In-Process Inspections, and Pre-Shipment Inspections. Product Quality Inspections evaluate the final output against specifications. Process Quality Inspections guarantee compliance during production stages. In-Process Inspections monitor quality in real-time, allowing for immediate corrections. Finally, Pre-Shipment Inspections confirm that finished products meet all standards before dispatch, assuring that customers receive defect-free items. Each type plays a critical role in maintaining quality. Conclusion To summarize, production quality inspection is essential for ensuring that products meet necessary standards, thereby reducing defects and enhancing efficiency. By implementing various inspection methods, such as visual checks and automated systems, manufacturers can identify issues early in the production cycle. This proactive approach not just minimizes costly recalls but likewise nurtures continuous improvement and customer trust. As technology advances, integrating innovative tools into quality inspections will further strengthen manufacturing processes and maintain competitive advantage in the market. Image via Google Gemini and ArtSmart This article, "What Is Production Quality Inspection and Why Is It Essential?" was first published on Small Business Trends View the full article

-

What Is Production Quality Inspection and Why Is It Essential?

Production quality inspection is a systematic process that guarantees your manufactured products meet specific quality, safety, and performance standards. By identifying defects early, you can prevent costly recalls and improve operational efficiency. Various inspection methods, such as visual checks and automated systems, play an essential role in maintaining quality throughout production. Comprehending the significance of these inspections and their impact on your business can help you elevate customer trust and comply with industry regulations, leading to greater competitive success. Key Takeaways Production quality inspection ensures products meet quality, safety, and performance standards, safeguarding both manufacturers and consumers. It identifies defects early in the production process, minimizing costly rework, scrap, and potential recalls. Various inspection types, including pre-production, in-process, and final checks, help maintain consistent quality throughout manufacturing. Technology, such as AI and IoT, enhances inspection accuracy and promotes real-time monitoring for immediate defect detection. Implementing quality inspections fosters customer trust, boosts operational efficiency, and supports continuous improvement initiatives within organizations. Understanding Production Quality Inspection Production quality inspection plays a crucial role in the manufacturing process, as it guarantees that products comply with established standards for quality, safety, and performance. This critical process occurs at various stages of production, helping you identify defects early, which reduces the risk of costly recalls. Different methods, such as visual checks, automated systems, and in-process evaluations, are employed to monitor compliance with industry regulations and customer specifications. By implementing effective production quality inspections, you improve operational efficiency and minimize waste, promoting a culture of continuous improvement. This approach not only contributes to customer satisfaction but also strengthens brand reputation, ensuring high-quality products reach the market, finally reflecting the effectiveness of quality control in manufacturing. The Importance of Quality Inspection in Manufacturing Effective quality inspection in manufacturing is crucial for guaranteeing that products meet the specified standards and remain free of defects. By implementing robust quality control in the manufacturing industry, you can safeguard your brand and build customer trust. Here are some key reasons why quality inspections are critical: Identify weaknesses in the production process early. Save costs by minimizing rework, scrap, and recalls. Guarantee compliance with industry regulations and standards. Improve operational efficiency by reducing defects and waste. Quality inspection not only protects consumers but equally strengthens your market position. Regular inspections facilitate continuous improvement, leading to better product quality and increased customer satisfaction. In the end, prioritizing quality inspections contributes greatly to your manufacturing success. Types of Quality Inspections Quality inspections play a crucial role in ensuring that products meet established standards throughout the manufacturing process. There are several types of quality inspections, including Pre-production checks, In-process inspections, and Final inspections. Each type focuses on different stages of the inspection process in manufacturing to prevent quality issues. Common methods include Visual inspection for surface defects, Automated systems for precision checks, and both Destructive and Non-destructive testing to assess material integrity and safety. Customizable checklists facilitate communication about quality concerns among stakeholders, ensuring specific product requirements are met consistently. These quality control inspections not only reduce defects and waste but also help maintain compliance with industry regulations, eventually enhancing operational efficiency and customer satisfaction. The Quality Inspection Lifecycle As manufacturers move through the production lifecycle, inspections become essential checkpoints that help guarantee adherence to quality and safety standards. The quality inspection lifecycle includes several key stages: Pre-production inspections assess the quality of raw materials before manufacturing begins. In-process inspections detect defects during active production, preventing issues from escalating. Final inspections verify that finished products meet specified requirements before shipment. Statistical sampling methods, like Acceptable Quality Level (AQL), optimize quality checks in manufacturing without exhaustive 100% checks. Benefits of Implementing Quality Inspections Implementing quality inspections offers numerous advantages that can greatly impact a manufacturing operation. By identifying defects early in the production process, you can markedly reduce rework and scrap costs, improving financial efficiency. Regular quality checking procedures guarantee compliance with industry regulations, minimizing the risk of fines as well as promoting accountability. Furthermore, effective quality inspection examples show that consistently meeting customer expectations leads to heightened satisfaction, brand loyalty, and repeat business. These inspections additionally boost operational efficiency by uncovering bottlenecks and streamlining processes, thereby improving productivity. Finally, the data gathered supports continuous improvement initiatives, allowing you to pinpoint trends and areas for development, ultimately strengthening your competitive position in the market. Statistical Sampling in Quality Inspection In many manufacturing environments, statistical sampling serves as a practical and efficient method for evaluating product quality without the burden of inspecting every single item produced. This cost-effective approach is crucial for quality control in production, especially in high-volume settings. Here are some key points about statistical sampling: Acceptable Quality Level (AQL) defines the maximum allowable defects in a sample. Common techniques include simple random, stratified, cluster, and systematic sampling. Identifies defect patterns and variations, helping manufacturers implement corrective actions. Structured sampling plans specify sample size and acceptance criteria aligned with industry standards. Embracing Technology in Quality Inspections Embracing technology in quality inspections greatly transforms the way manufacturers guarantee product reliability. Automated systems like machine vision and artificial intelligence improve accuracy, considerably reducing human error in inspection and quality control in manufacturing. With advanced technologies such as IoT, you can monitor production processes in real-time, allowing for the immediate identification of defects. AI-powered visual inspection systems excel at detecting minute flaws that manual inspections might miss, thereby enhancing quality assessments. Additionally, integrating data analysis software helps identify trends and areas for improvement, streamlining the inspection process. Robotics and automation not just accelerate quality checks but also boost overall operational efficiency, making a considerable impact on improving quality control in manufacturing environments. Building an Effective Quality Inspection Program To build an effective quality inspection program, you must first develop a thorough inspection plan that aligns with specific products and processes. This plan should focus on how to improve quality control in production by incorporating various strategies, such as: Defining clear roles and responsibilities for inspection personnel. Utilizing advanced technologies like AI and machine vision for improved accuracy. Conducting regular audits of inspection processes to identify improvement areas. Offering continuous training for staff to stay updated on best practices. Continuous Improvement in Quality Inspection Continuous improvement in quality inspection plays a crucial role in enhancing product quality and operational efficiency across manufacturing processes. By identifying and addressing root causes of defects, you can greatly boost product quality checks. Cultivating a culture of continuous improvement encourages every employee to participate in quality initiatives, promoting innovation and accountability. Regular audits and evaluations of your inspection processes yield critical insights, guiding corrective and preventive actions to guarantee compliance with industry standards. Leveraging data from inspections helps you pinpoint trends and streamline processes, finally enhancing your quality management systems. Furthermore, ongoing training, like access to Six Sigma resources, equips your staff with the skills needed to contribute effectively to these continuous improvement efforts in quality inspection practices. The Future of Quality Inspection in Manufacturing As manufacturing evolves, the future of quality inspection is being shaped by state-of-the-art technologies that improve efficiency and precision. You can expect significant advancements in manufacturing inspection through: Automation and AI for improved accuracy in defect detection IoT integration for real-time monitoring of production processes Data analytics for predictive quality management, anticipating defects before they occur Proactive quality inspection programs that emphasize continuous improvement These innovations streamline qc checks, ensuring that quality issues are identified and resolved without delay. As customer expectations rise, manufacturers are investing in sophisticated inspection systems that not only comply with regulations but also cultivate brand loyalty by delivering consistently high-quality products. Adapting to these changes will be key to staying competitive in the manufacturing environment. Frequently Asked Questions Why Is Inspection Important in Production? Inspection in production is essential since it helps you catch defects early, preventing costly recalls and guaranteeing your products meet quality standards. By conducting regular inspections, you reduce waste and improve operational efficiency, which can lead to better financial performance. Inspections also guarantee compliance with industry regulations, protecting your business from legal issues. Addressing potential problems before finalizing products saves time and builds your brand’s reputation, nurturing customer trust and loyalty. What Is the Primary Purpose of Quality Inspection? The primary purpose of quality inspection is to guarantee your products meet established standards for quality, safety, and performance. By identifying defects early, you can prevent costly recalls and improve customer satisfaction. Quality inspections additionally help you comply with industry regulations, protecting consumer safety as well as avoiding fines. Furthermore, a systematic approach cultivates a culture of continuous improvement, encouraging your team to take responsibility for maintaining high product quality and operational excellence. What Is Production Inspection? Production inspection is a systematic process where you check products at various stages of manufacturing to guarantee they meet quality standards. This includes Initial Production Checks, During Production Inspections, and Pre-Shipment Inspections, focusing on different points in the production cycle. Certified inspectors use customized checklists to evaluate product specifications, packaging, and production progress. By identifying defects early, you minimize risks and costs, leading to improved efficiency and better overall product quality. What Are the 4 Types of Quality Inspection? The four types of quality inspections in manufacturing are Product Quality Inspections, Process Quality Inspections, In-Process Inspections, and Pre-Shipment Inspections. Product Quality Inspections evaluate the final output against specifications. Process Quality Inspections guarantee compliance during production stages. In-Process Inspections monitor quality in real-time, allowing for immediate corrections. Finally, Pre-Shipment Inspections confirm that finished products meet all standards before dispatch, assuring that customers receive defect-free items. Each type plays a critical role in maintaining quality. Conclusion To summarize, production quality inspection is essential for ensuring that products meet necessary standards, thereby reducing defects and enhancing efficiency. By implementing various inspection methods, such as visual checks and automated systems, manufacturers can identify issues early in the production cycle. This proactive approach not just minimizes costly recalls but likewise nurtures continuous improvement and customer trust. As technology advances, integrating innovative tools into quality inspections will further strengthen manufacturing processes and maintain competitive advantage in the market. Image via Google Gemini and ArtSmart This article, "What Is Production Quality Inspection and Why Is It Essential?" was first published on Small Business Trends View the full article

-

If You've Installed Any of These 17 Browser Extensions, Delete Them Now

Another wave of malicious browser extensions capable of tracking user activity and compromising privacy have been found across Chrome, Firefox, and Edge, some of which may have been active for up to five years. The campaign, known as GhostPoster, was identified by Koi Security in December and included 17 Firefox add-ons designed to monitor users' browsing activity. Threat actors planted malicious JavaScript code in the extension's PNG logo, which served as a malware loader to retrieve the main payload from a remote server. Researchers at LayerX have found an additional 17 malicious extensions across multiple browsers that have collectively been installed more than 840,000 times. Ongoing GhostPoster malware campaignAccording to the report from LayerX, GhostPoster initially targeted Microsoft Edge and then expanded to Chrome and Firefox. The malicious add-ons may have been active as early as 2020 and include the following: Google Translate in Right Click Translate Selected Text with Google Ads Block Ultimate Floating Player – PiP Mode Convert Everything Youtube Download One Key Translate AdBlocker Save Image to Pinterest on Right Click Instagram Downloader RSS Feed Cool Cursor Full Page Screenshot Amazon Price History Color Enhancer Translate Selected Text with Right Click Page Screenshot Clipper "Google Translate in Right Click" alone had 522,398 installs. The next most popular add-on was "Translate Selected Text with Google" with 159,645 installs. Researchers also found a more sophisticated variant of the campaign in "Instagram Downloader," which had 3,822 installs. GhostPoster malware has built-in safeguards to prevent detection—for example, activation is delayed by 48 hours, and it only communicates with remote attack servers under certain conditions. Once installed, though, extensions that are part of GhostPoster have the ability to hijack affiliate traffic (and redirect commissions to attackers), strip and inject HTTP headers to weaken security, bypass CAPTCHA, and inject iframes and scripts for click fraud and user tracking. The only sort-of good news is that the malware doesn't harvest credentials or engage in phishing. While the malicious extensions are no longer available to add in Chrome, Edge, and Firefox, users who have them installed should remove them immediately, as they remain active until explicitly deleted. View the full article

-

This simple, three-step framework is the secret to success under pressure

Leadership loves speed. You see it in job postings: “We’re a fast-paced environment.” And you hear it: “Decide quickly.” “Respond ASAP.” “Fix it… now.” And yes, action needs to happen at work. But reacting quickly and leading effectively aren’t the same thing. Some of the biggest leadership mistakes don’t happen because someone’s careless. They happen because someone feels pressure to respond immediately and prioritizes urgency over accuracy. Someone makes a mistake and you groan. You hear feedback and go on the defensive before you’ve even fully heard it. Someone gets sick during a key project and your first thought is, “How will this get done now?” These moments pass fast, but the ripple effects linger. That’s why leaders can use a simple framework that creates better decisions and better conversations without slowing down the work: Pause-Consider-Act. Not because leaders need to become slower. Because they need to become steadier. Here’s how it works. Step 1: Pause (not stop) When leaders hear the word “pause,” they sometimes picture a dramatic freeze or a long, awkward silence while everyone waits for a decision. That’s not what this is. Pausing isn’t stopping. It’s creating an opportunity to think before you respond. A pause can be as small as a breath before you speak. It can be a quick reset of your tone and your words. That beat matters because without it, pressure changes the way you lead. Your tone gets sharper. Your patience gets thinner. Your words get shorter. Your brain goes into “handle it now” mode instead of “handle it well” mode. It’s not a character flaw—it’s human. But leadership is the ability to respond without letting stress take the wheel. If you want words to have ready when you’re on the spot, try these: “I want to make sure I answer this the right way. Let me take a second.” It buys you time without creating uncertainty. It signals confidence, not weakness. And it keeps a tense moment from becoming a bigger one. Step 2: Consider (the full picture) When you pause, you have room to consider what’s actually happening. Not just the words being said, but what’s underneath them. “Consider” isn’t about being soft. It’s about being fair and smart. It means running decisions through a simple filter: How would I want to be treated if this were me? Or: How would I a loved one treated in this situation? It doesn’t mean you avoid accountability. It means you stop treating people like problems to solve and start treating them like humans to lead. In the Consider step, ask yourself: · What might I be assuming that I don’t actually know? · What outcome am I aiming for here? · If this were someone else, would my response be the same? That last question matters more than people want to admit. Because inconsistency is one of the fastest ways to lose trust. Employees can handle tough feedback. What they struggle to handle is unpredictability. Step 3: Act (follow through) Strong leadership action is direct, calm, and specific. It’s not vague promises or reassurance. It’s saying what needs to be said, without making someone feel uncertain or ashamed in the process. And this is where leaders sometimes slip: they pause, consider… and then never actually act. They avoid the conversation—saying “I’ll circle back,” but never do. Or they soften a message, so it’s not actually heard. If you want your team to trust you, action has to include follow-through, even if it’s simple: · Here’s what I’m doing. · Here’s what I need from you. · Here’s when we’ll check in again. Clear communication builds trust. And trust is what makes teams more efficient, more resilient, and easier to lead long-term. What this looks like in real leadership moments Pause-Consider-Act matters most in the moments that test you. If someone makes a mistake, instead of groaning or snapping, try: “Let’s look at what went wrong and how we fix it and from it.” If you get feedback, instead of becoming defensive, say: “Thank you for telling me. I want to think on that and talk more about it.” If someone gets sick during a key project, instead of stress, respond: “First, take care of yourself. We’ll figure out coverage and next steps.” Pause-Consider-Act won’t make every situation easy. But it gives you a repeatable way to lead reliably, especially when your first instinct is to move fast. Because the leaders who build the most trust aren’t the fastest to respond. They’re the ones who know how to pause, consider, and act with intention. View the full article

-

The real reason stress keeps coming back at work

Stress doesn’t usually announce itself. It shows up as back‑to‑back meetings. A constantly full inbox. That feeling of being busy all day but unsure what actually moved. And for many people, it feels normal. Until it doesn’t. When pressure becomes the default In our recent Stop the Stress Cycle skills booster, we shared one pattern that came up again and again. People aren’t overwhelmed because they can’t cope. They’re overwhelmed because work has slipped into a permanent state of urgency. Decisions get rushed. Thinking time disappears. Everything feels important, so nothing gets proper attention. Why stress keeps repeating itself at work One of the biggest myths we explored is that stress is mainly about workload. In reality, it’s more often driven by how work is structured day to day. Constant interruption. Unclear priorities. No space to recover between demands. When those conditions are in place, stress becomes self‑reinforcing. People react more. They plan less. The cycle tightens. Watch the recording If everything feels urgent, this recording will help you step back and see what’s really going on. It’s especially useful if: • Your days are full but your head is fuller • You’re stuck in reactive mode • You want calmer, more sustainable performance Sometimes the most productive thing you can do is pause long enough to choose a better way forward. If this resonated for you or your team, many organisations explore these ideas further through our wider productivity and wellbeing workshops. They focus on helping people slow down, reduce reactivity, and create practical habits that protect energy and attention in everyday work. The post The real reason stress keeps coming back at work appeared first on Think Productive UK. View the full article

-

US pushes Russia and Ukraine towards direct talks in Abu Dhabi

Donald The President’s envoys to travel to Moscow to discuss idea of trilateral meeting with Vladimir Putin View the full article

-

Coalition backs 3 ways to cut housing costs without Congress

Reducing agency loan pricing adjustments and credit reports may help, a trio of industry groups wrote in a letter to the National Economic Council's director. View the full article

-

10Web WordPress Photo Gallery Plugin Vulnerability via @sejournal, @martinibuster

10Web Photo Gallery plugin vulnerability enables unauthenticated attackers to delete image comments. The post 10Web WordPress Photo Gallery Plugin Vulnerability appeared first on Search Engine Journal. View the full article

-

Warren Buffett on the everyday habits that quietly build extraordinary success

Sometimes Warren Buffett says something so simple, so obvious, that you almost want to roll your eyes. At 95 years young, he has offered plainspoken advice that has shaped one of the most successful careers in history. But when you hear it, you know it’s truth and part of you wonders: Why haven’t I applied this yet? When we slow down long enough to sit with some of his wisdom—really let it sink in, not just skim it on our phones—his principles can reshape how we lead, how we work, and how we show up in life. The challenge, of course, is in the follow-through. How many of us can read something today and honestly say, “I’m going to start doing this tomorrow”? If you’re feeling even a little inspired, here are six Buffett classics worth putting into practice. Break the habits that hold you back Most of us know exactly what’s holding us back. Buffett doesn’t sugarcoat it. He once told a group of college grads, “I see people with these self-destructive behavior patterns. They really are entrapped by them.” His message was simple: Build better habits early, because the longer you wait, the harder it gets. “The chains of habit are too light to be felt until they are too heavy to be broken,” added Buffett. This is leadership 101. Your people won’t rise above the behaviors you tolerate in yourself. Don’t gamble what matters most Buffett told those same students that he’s watched countless leaders and companies blow up their lives chasing something bigger—usually out of greed or impatience. His filter is straightforward: “If you risk something that is important to you for something that is unimportant to you, it just doesn’t make sense.” Leaders often get in trouble not because they lack intelligence, but because they lose perspective. Surround yourself with people who do what’s right Buffett asked students to think of the classmate whose long-term success they’d bet on. The qualities they’d identify? Integrity. Humility. Generosity. “That would be the person who is generous, honest, and who gave credit to other people for their own ideas,” he said. Integrity in the age of liars and narcissists is your competitive advantage. People follow leaders they trust. Stay in the lane where you excel Buffett once quoted Tom Watson Sr., founder of IBM: “I’m no genius. But I’m smart in spots, and I stay around those spots.” Leaders get themselves into trouble when they drift too far from their strengths. Know your lane. Build from it. Delegate what sits outside it. That focus is what creates mastery and a career you can be proud of. Build a career you actually love This one feels almost too obvious, but most people ignore it for decades: “In the world of business, the people who are most successful are those who are doing what they love,” said Buffett. Too many leaders stay in roles that drain them simply because the paycheck feels safe. But when you do work that energizes you, everything—creativity, resilience, performance—gets better. Choose people who raise your standards At a 2004 Berkshire Hathaway annual meeting, Buffett told a 14-year-old: “It’s better to hang out with people better than you. Pick out associates whose behavior is better than yours and you’ll drift in that direction.” This is one of the most underrated leadership truths. We absorb the standards of the people around us. You want to grow? Surround yourself with leaders who elevate you. When you strip away the mystique around success, Buffett’s tips leave us with a clear reminder that it doesn’t have to be complicated or grand. Your success is built on small, steady choices—habits, relationships, focus, integrity. All of it is transformative if you take it seriously. Look back at that list. Now, pick one principle and start practicing it today. That’s how real change happens, for you and for the people you lead. Like this article? Subscribe here for more related content and exclusive insights from executive coach and global speaker Marcel Schwantes. —Inc. View the full article

-

Tariff reprieve jolts markets, Treasury gaps loom

Markets brushed off mixed, stale data as tariff news sparked a brief rally, but open Treasury gaps kept bond signals cautious, according to the CEO of IF Securities. View the full article

-

Elon Musk’s SpaceX lines up 4 banks for blockbuster IPO

Bank of America, Goldman Sachs, JPMorgan Chase and Morgan Stanley set to take lead on listingView the full article

-

Google Launches Personal Intelligence In AI Mode via @sejournal, @MattGSouthern

Google's Personal Intelligence connects Gmail and Google Photos to AI Mode, delivering personalized responses for AI Pro and Ultra subscribers. The post Google Launches Personal Intelligence In AI Mode appeared first on Search Engine Journal. View the full article

-

Google brings Personal Intelligence to AI Mode in Google Search

Personal Intelligence, which was introduced first on the Gemini app last week, is already rolling out to some users in AI Mode within Google Search. “Starting today, Google AI Pro and AI Ultra subscribers can opt-in to securely connect Gmail and Google Photos to AI Mode,” Robby Stein, VP of Product, Google Search announced. Personal Intelligence in AI Mode lets Google Search give you a more personal response to your queries by connecting across your Google ecosystem, including Google Search, Gmail, Photos, and your YouTube history. This is rolling out over the next few days AI Pro and Ultra subscribers in English in the U.S. How to see it. This is a Labs feature and you can opt in to this feature over here. It is available for Google AI Pro and Ultra subscribers in English in the U.S. Google said these users “will automatically have access to the feature as it becomes available.” This feature is available for personal Google accounts but not for Workspace business, enterprise or education users, yet. You can try to manually turn it on in your settings, by taking these steps: 1) Open Search and tap your profile 2) Click on Search personalization 3) Select Connected Content Apps 4) Connect Workspace and Google Photos Examples. Here are some examples of questions you could ask: Help me plan a weekend getaway with my family based on things we like to do Make a scavenger hunt for [partner’s name] to celebrate our anniversary. For each location, include a hint about us I’m decorating [child’s name] bedroom, give me ideas for a theme and suggestions for decor If I were the heroine/hero from a book, who would I be? What specific era of fashion do I actually belong in? Recommend some books that fit where I am in my life right now If I were a perfume [or cologne], what would my top notes and base notes be? Here is a video of it in action: Why we care. Again, this is currently opt in only, as a search labs experiment. One day, it might graduate and become a default Google Search experience within AI Mode. The results will become more and more personalized and tracking which website citations show up for one searcher versus another search, will become harder and harder. View the full article

-

Pantone just made a color matching starter kit for only $99

Pantone’s professional color matching kits can cost anywhere from several hundred dollars to upwards of several thousand dollars for pros who work in industries like fashion and interiors. Its newest, though, is a single-fan book with more than 600 spot colors, and it’s priced at just $99. Pantone for beginners. Pantone on Thursday announced its Pantone Capsule: Signature Edition. Housed in a collectible, cylindrical case that wouldn’t look out of place in a Sephora, the guide is a sort of Pantone 101 that come on coated and uncoated paper stock with colors selected from across more than 60 years of Pantone history. “At Pantone, we have spent a lot of time speaking with our creative community to understand how their roles have changed, the tools they need, and how to best serve them,” Ora Solomon, Pantone’s vice president of product and engineering, said in a statement. “As a result, we wanted to expand the opportunities for our design community to have a more accessible way to use our guides, especially at the beginning of their careers, and help them create with confidence.” The colors for the collection were chosen for their utility, based on Pantone data about the most popular and widely used colors. There’s Pantone 6104 C, a sapphire blue that’s one of its newest colors, and retro throwbacks, like the bright yellow Pantone 102 C and the purple-pink Pantone 238, which were popular in the 1980s and ’90s. The Pantone capsule represents something of a departure for the color-matching company’s product releases, since it usually adds colors to its existing standard formula guide instead of curating new guides. The idea for it came from Pantone’s creative listening initiative to work directly with creatives in order to improve its products. After being previewed with designers at Adobe Max in October, Pantone says the reaction was enthusiastic. Pantone imagines the guide as a primer on the Pantone Matching System for students and content creators, or a portable companion for freelancers between clients and project. Or even just for fun, since it was designed to be collectible. While Pantone’s business is verifying colors, initiatives likes its long-running Color of the Year and collaborations with celebrities, bands, and brands have made Pantone a popular authority on color. An affordably priced, mobile color-matching starter kit that also happens to look good on a shelf manifests that ethos in a physical, accessible way. View the full article

-

how do I adjust to a position that’s full-time desk work?

It’s the Thursday “ask the readers” question. A reader writes: I saw a question about switching back to the office after working from home, and thought I’d throw the opposite out there. My previous jobs have all been mandatory on-site, with a mix of hands-on procedures and computer-based work. Relatively soon, I’ll be moving to a position that is both 100% desk work and remote (full-time WFH is, for many reasons, not for me, so I’ll be joining a co-working space). This job is a great fit in many ways and I’m excited about it, but I’m looking for ideas of how to make 100% desk work sustainable. I’m a very active person, so I think I’m going to miss all the motion during the workday. And, when I have had stretches of mostly desk work, I’m tired and out of sorts by the end of the day from staring at a screen for so long. For anyone who’s made a similar transition, how did it go? What strategies would you recommend to minimize the tedium, keep track of the passage of time, and avoid becoming one with the office chair? Finally, tips on avoiding screen burnout? I use blue light glasses; I’m looking more for advice on the mental end of it. 8-10 hours at the computer leaves me feeling burnt out and ineffective, even though I have no problem doing that same quantity of high-concentration physical work. Readers, what’s your advice? The post how do I adjust to a position that’s full-time desk work? appeared first on Ask a Manager. View the full article

-

A Breakdown Of Microsoft’s Guide To AEO & GEO via @sejournal, @martinibuster

Microsoft explains what matters for AEO and GEO and details three strategies that influence AI recommendations. The post A Breakdown Of Microsoft’s Guide To AEO & GEO appeared first on Search Engine Journal. View the full article